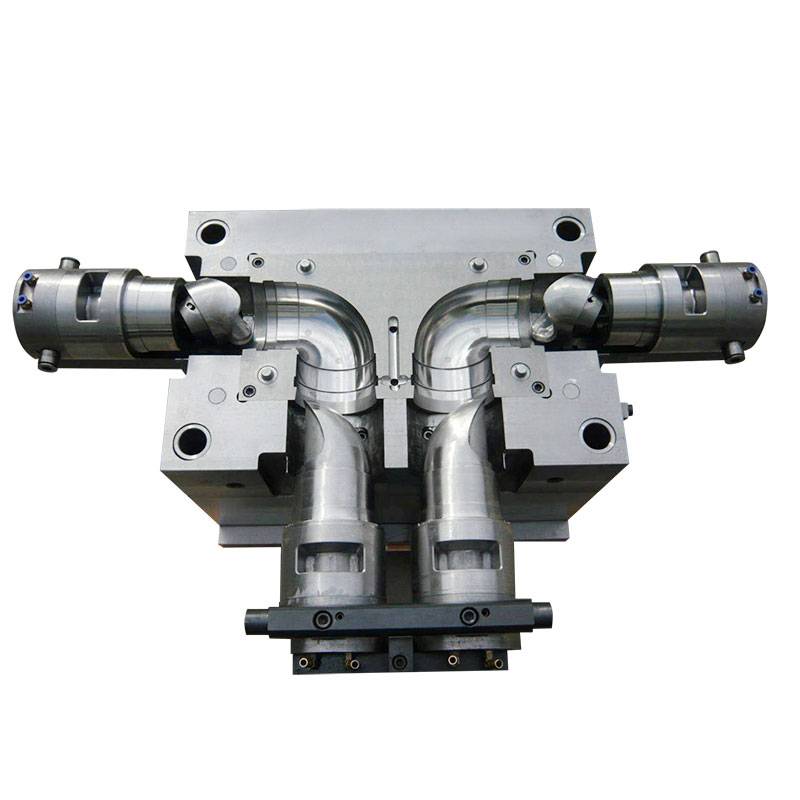

China wholesale Cpvc Pipe Fitting Mould - PPR 45° Elbow Pipe Fitting Mould – Longxin

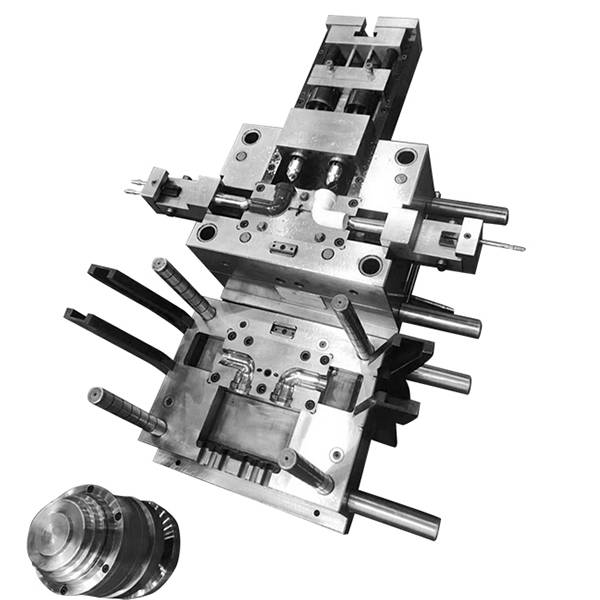

China wholesale Cpvc Pipe Fitting Mould - PPR 45° Elbow Pipe Fitting Mould – Longxin Detail:

Introduce

Quick details

Origin: Taizhou, Zhejiang, China

Brand: PPR mould

Model: PPR 45°Elbow Pipe Fitting Mould

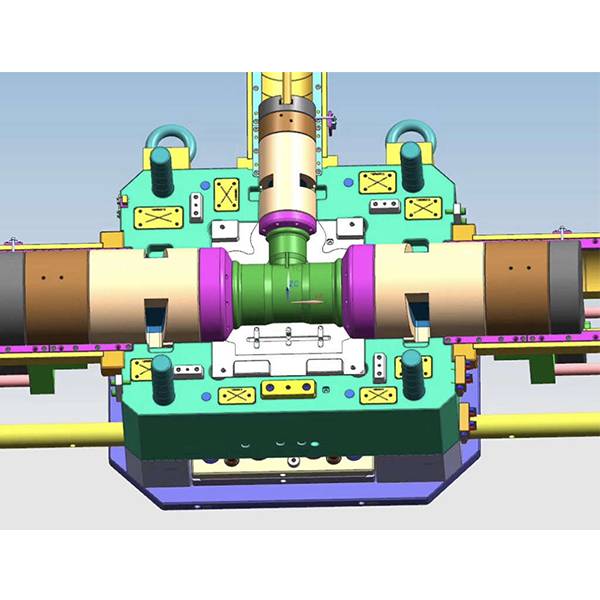

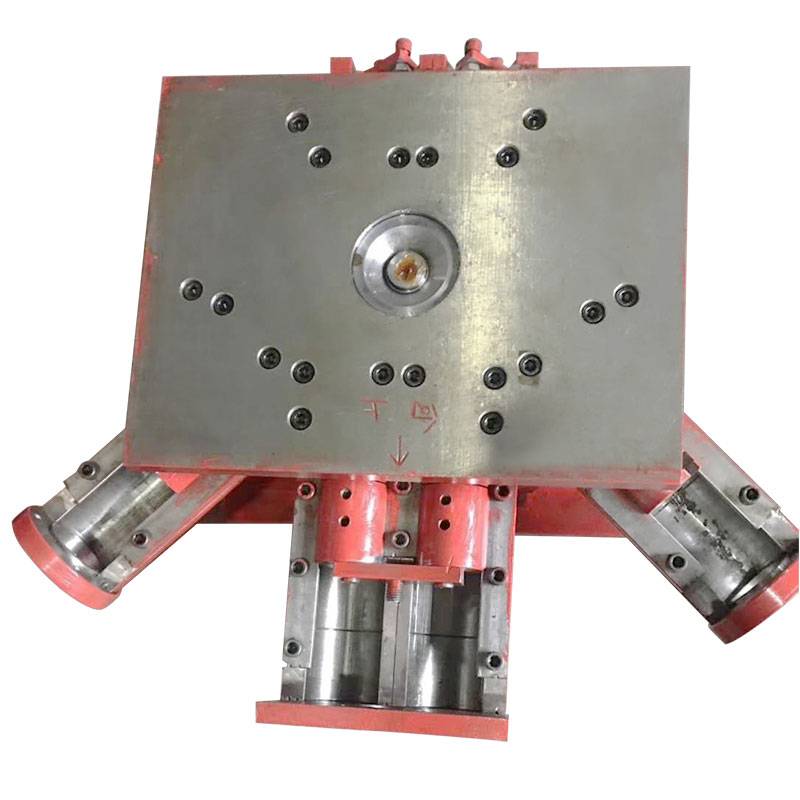

Moulding mode: plastic injection mould

Product material: Steel

Products: household goods

Name: China high quality plastic PPR pipe fitting mould

Cavity: 8-12 cavities

Design: 3D or 2D

Runner type: cold runner

Die steel: p20h / 718 / 2316 / 2738, etc

Mould base: LKM, HASCO, DME

Mould life: 500000

Sampling time: 60-90 days

Colors: all colors

The Material

Our PPR 45° Elbow Pipe Fitting Mould, manufactured using the best quality steel and the most reasonable workmanship, has the following characteristics

1. The steel material used for our 45° Elbow Pipe Fitting Mould is: Steel plate S50C, P20, P20HH, 718H, 2738H, H13, S136, NAK80

2. Hardness (HRC) of the steel we choose: 17-22, 27-30, 33-37, 33-38, 36-40, 45-52, 48-52, 34-40

3, the cooling water system and the gate design according to the requirements of the product structure characteristics and product appearance design reasonable form of gate, a big gate, latent type gate and the fan gate, needle valve type, etc., reasonable flow channel structure design can make the mould in the shortest possible time balance mould temperature, in order to improve the precision of products and production efficiency

4. Wear resistant standard parts such as insert, guide post, guide sleeve, slide block, sliding block and inclined top block are adopted in the configuration of spare parts to improve the service life of the mould.

5. Mold surface treatment and mirror polishing;

6. Mold production cycle is expected to be 20-50 seconds

7. The service life of the target mold is more than 500,000 molds

8. It will take 60-90 days to complete the mold

Our Services

How to pack PPR 45°Elbow Pipe Fitting Mould flaring in wooden case:

First: Daub rust preventive oil on the mould.

Second: We pack the mold with thin plastic film to avoid moisture.

Third: We put this plastic film packed mould in a wooden box, and fix it avoid any movement.

Packing size of wooden case: according to mould size

Port:Ningbo

Product detail pictures:

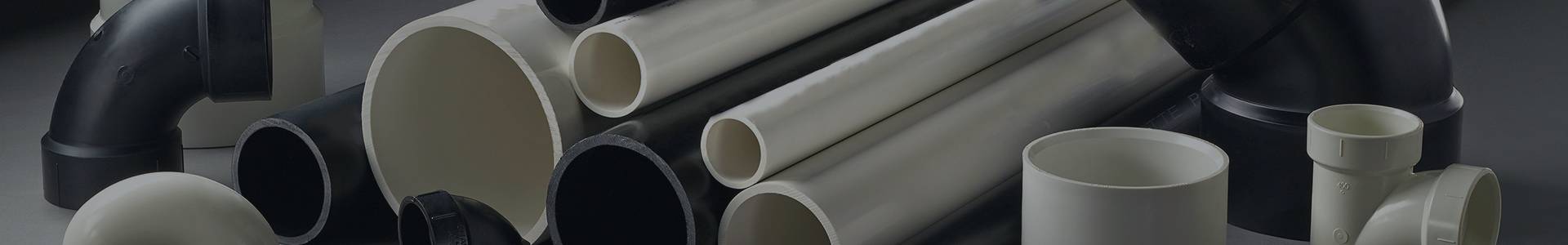

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for China wholesale Cpvc Pipe Fitting Mould - PPR 45° Elbow Pipe Fitting Mould – Longxin , The product will supply to all over the world, such as: Belarus, UK, Israel, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.