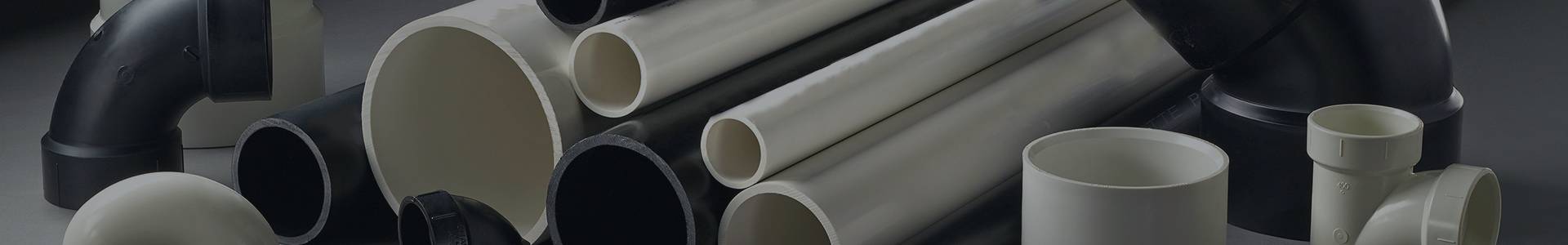

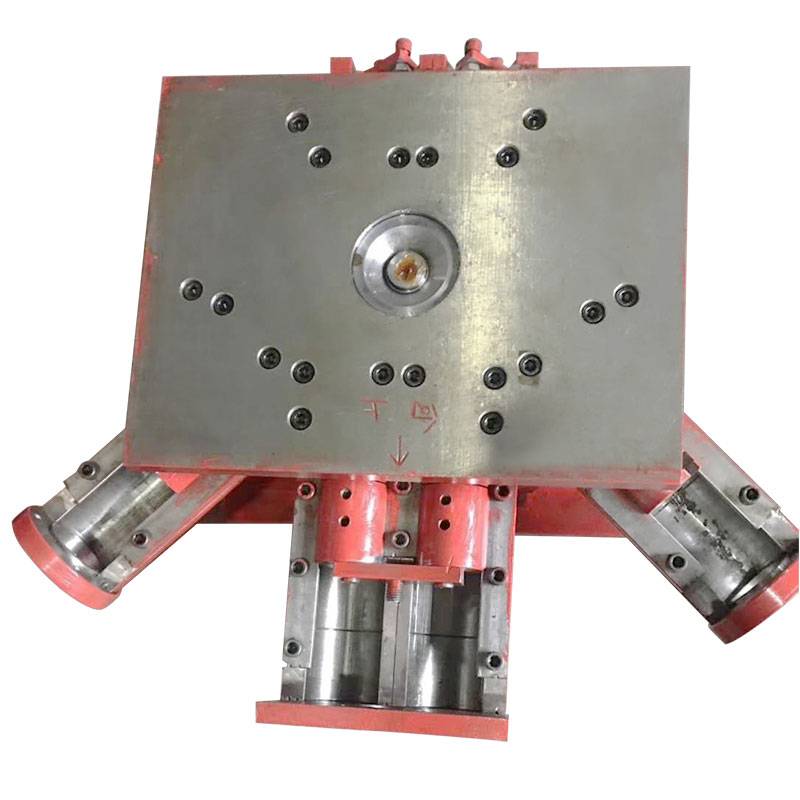

Best quality Plastic Pvc Pipe Fitting Injection Mold - UPVC Yee Tee Pipe Fitting Mould – Longxin

Best quality Plastic Pvc Pipe Fitting Injection Mold - UPVC Yee Tee Pipe Fitting Mould – Longxin Detail:

Quick Details

Origin: Taizhou, Zhejiang, China

Brand: UPVC mould

Model:UPVC Yee Tee Pipe Fitting Mould

Moulding mode: plastic injection mould

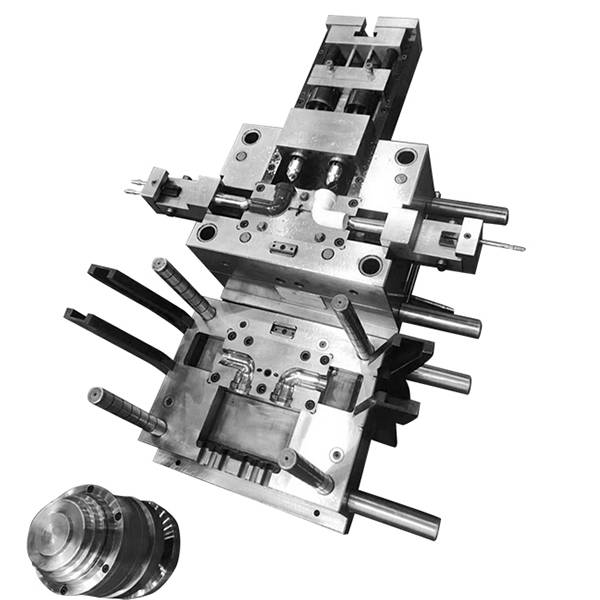

Product material: Steel

Products: household goods

Name: China high quality plastic UPVC Yee Tee Pipe Fitting Mould

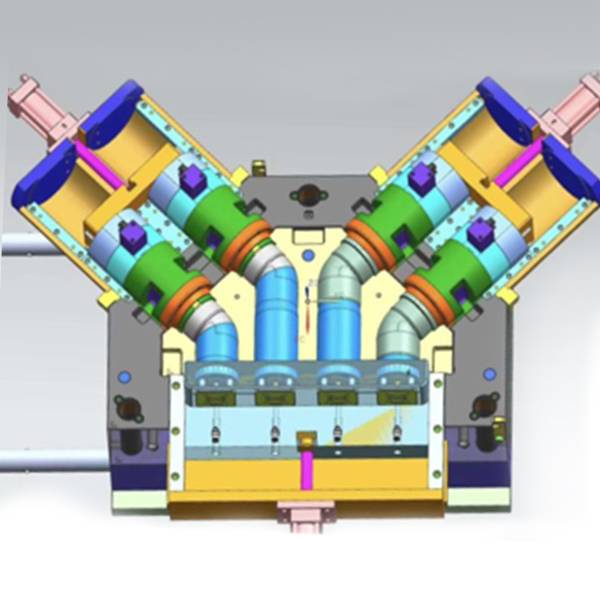

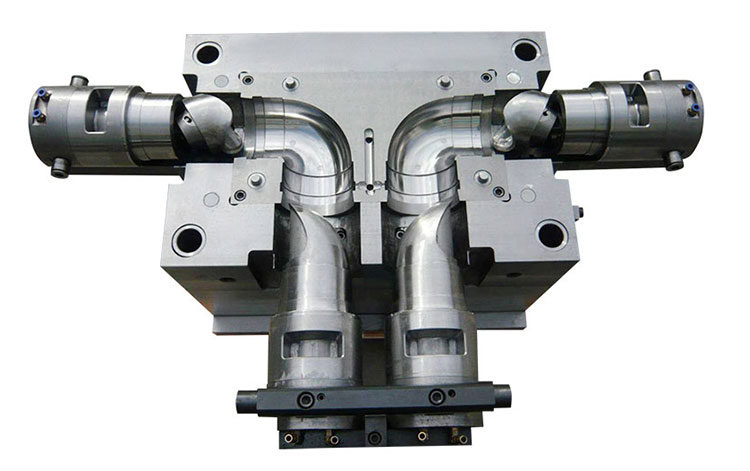

Cavity: 2 cavities

Design: 3D or 2D

Runner type: cold runner

Die steel: p20h / 718 / 2316 / 2738, etc

Mould base: LKM, HASCO, DME

Mould life: 500000

Sampling time: 60-90 days

Colors: all colors

| The main Mould Steel and Hardness for you reference: | ||||||||

| Steel Grade | S50C | P20 | P20HH | 718H | 2738H | H13 | S136 | NAK80 |

| Hardness(HRC) | 17-22 | 27-30 | 33-37 | 33-38 | 36-40 | 45-52 | 48~52 | 34-40 |

Pipe Fitting Mould Features :High Automation multi cavities ,high precision,high productivity, long-lasting lifeWe have our own unique design for some moulds,

Our services

We longxin adhering to the principle of quality first, service first to serve each of our customers, professional production of PVC Sewage Or Y Tee Pipe Fitting Mould, Welcome to call and order

1. In-time response on letters, telephone calls or fax

2. In-time supply the quotation and mould designs

3. In-time sending pictures for the mould machining progress and mould finishing schedule

4. In-time sending pictures for the mould machining progress and mould finishing schedule

5. In-time mould delivery.

For more information please contact us.

Packing and delivery

How to pack PVC Tee Pipe Fitting Mould flaring in wooden case:

First : Daub rust preventive oil on the mould.

Second : We pack the mold with thin plastic film to avoid moisture.

Third : We put this plastic film packed mould in a wooden box, and fix it avoid any movement.

Packing size of wooden case: according to mould size

Port:Ningbo

FAQ:

Finally, a pair of pipe fitting molds have been made. Next, we have to test the effectiveness of the mold, that is, mold trial. Then put it into production, and how to maintain the mold during production, so that the mold can be in a better working condition and let us reap the greatest benefits?

Below we will introduce the things that we should pay attention to when trying out our pipe fitting molds for this UPVC Yee Tee pipe fitting molds:

1. Whether the mold opening and closing is smooth, and whether the ejection is smooth.

2. Pay attention to the position of the mold gate and the way of glue feeding, the size of the gate and the size of the cavity, and select the appropriate pressure, speed, and material volume for injection molding. 3. After the mold heats up, carefully check whether all the matching parts of the mold are too hard, and then confirm the bonding line and exhaust. After the product is full, ask the quality personnel to confirm the size and appearance.

4. During the mold production process, check the mold settings and safety devices to let the operating staff understand the possible problems in the process. After the production is completed, the lower mold or standby needs to take necessary measures for the machine and mold.

5.When the mold is not in production, the pipe fitting mold should be maintained. First check the mold and determine the maintenance method. If you need to disassemble the parts, first check whether there is a clear mark. After the maintenance of the parts is completed, the assembly should be matched and seated. After the assembly is completed, first confirm the sequence of the mold. Pay attention to the careful inspection and confirmation of the first piece after each maintenance, and the production can be continued after the quality personnel confirm OK.

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Best quality Plastic Pvc Pipe Fitting Injection Mold - UPVC Yee Tee Pipe Fitting Mould – Longxin , The product will supply to all over the world, such as: Tanzania, Muscat, San Diego, With the first-class solutions, excellent service, fast delivery and the best price, we've won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.